Positive Displacement Pumps

Type of pump in hydraulic system

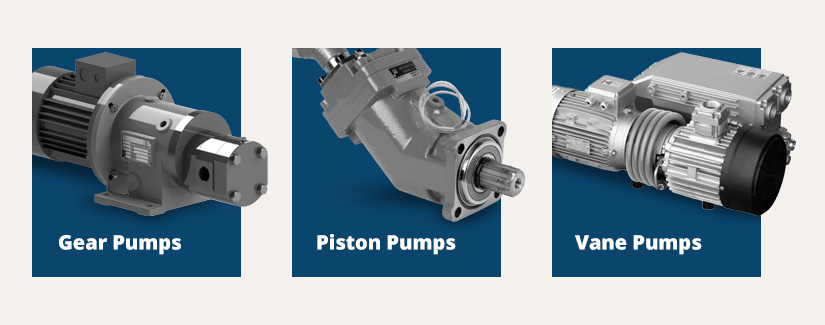

Gear Pumps

This type of pump in hydraulic system Gear pumps are one of the most common types of positive displacement pumps. They operate by using meshing gears to trap fluid and move it from the inlet to the outlet. Gear pumps are known for their simplicity, reliability, and suitability for low-pressure applications.

Piston Pumps

Piston pumps utilize reciprocating pistons to move fluid through the system. They offer high efficiency and are capable of handling high pressures. There are two main types of piston pumps: axial piston pumps and radial piston pumps.

Vane Pumps

Vane pumps feature retractable vanes that rotate within a housing. As the vanes extend and retract, they create chambers that draw in and expel fluid. Vane pumps are known for their smooth operation and ability to handle varying viscosities.

Dynamic Pumps

Centrifugal Pumps

Centrifugal pumps are widely used dynamic pumps that rely on centrifugal force to move fluid. They work by converting kinetic energy into pressure energy. Centrifugal pumps are suitable for transferring large volumes of fluid at relatively low pressures.

Axial Piston Pumps

Axial piston pumps operate by using pistons arranged in a circular array within a cylinder block. These pumps are highly efficient and are often used in heavy-duty applications where high pressure is required.

Radial Piston Pumps

Similar to axial piston pumps, radial piston pumps also use pistons for fluid displacement. However, the pistons are arranged radially around a central cylinder block. These pumps are capable of handling extremely high pressures.

Comparing Positive Displacement and Dynamic Pumps

The choice between positive displacement and dynamic pumps depends on factors such as pressure requirements, flow rates, and efficiency. Positive displacement pumps provide consistent flow regardless of pressure changes, while dynamic pumps are better suited for applications requiring high flow rates.

Selecting the Right Pump for Your Hydraulic System

When selecting a pump for a hydraulic system, factors such as system pressure, flow rate, viscosity of the fluid, and space constraints must be considered. Proper pump selection ensures optimal system performance and longevity.

Common Applications of Hydraulic Pumps

Hydraulic pumps find applications in various industries, including construction, manufacturing, agriculture, and aviation. They power essential machinery like bulldozers, injection molding machines, presses, and landing gear systems.

Maintenance and Troubleshooting

Regular maintenance is essential to keep hydraulic pumps operating smoothly. Common issues include leaks, cavitation, and excessive noise. Addressing these problems promptly can extend the lifespan of the pump and improve system efficiency.

Advancements in Hydraulic Pump Technology

Advancements in hydraulic pump technology are focused on improving efficiency, reducing energy consumption, and enhancing durability. Variable displacement pumps, electronic controls, and smart monitoring systems are examples of these innovations.

Environmental Considerations

As industries become more environmentally conscious, hydraulic pump manufacturers are working to develop pumps with reduced emissions and lower energy consumption. This aligns with the global shift towards sustainability.

Conclusion

Type of pump in hydraulic system is the heart of hydraulic systems, enabling the operation of various machinery and equipment across industries. Understanding the different types of pumps, their functionalities, and their applications is essential for selecting the right pump for your specific needs.

As technology continues to evolve, hydraulic pumps will play a significant role in shaping the future of various sectors.